The innovative Ingelia design maximizes the advantages of HTC as the most efficient valorisation technology for every type of organic material

The Ingelia plant is designed to be flexible, scalable, and simple

-

The Ingelia plant is capable to treat different types of biomasses, at all humidity levels (30%-90% humidity).

-

The biomass collection and input system is defined according to each specific project.

-

The modular technology allows to size the plants according to the available quantity of raw material, facilitating its operation and maintenance, as well as increasing treatment capacity

The efficient design minimizes Capex, Opex and maintenance costs

-

Ingelia’s HTC plants work in continuous operation and therefore optimize energy balance as the conditions of pressure and temperature inside reactors does not vary.

-

The plant does not include heat exchangers or moving parts.

-

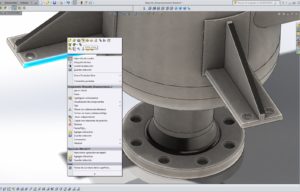

The equipment is developed and drawn with 3D and 2D software.

-

The plant control system allows remote access and enables a 24×7 surveillance.

The specific plant performance ensures the recovery of all valuable elements contained in the input biomass

-

The plant is self-sufficient in water and has low power consumption.

-

It recovers the heat from the output pipes for preheating the input mix, optimizing energy balance.

-

It extracts the oils contained in biomass, to be used as biochemical and it also prevents its presence in the process effluent allowing it to be used for irrigation

-

Plant operation is simple with low levels of noise and odours and without emissions in the area of process.

-

Equipment is selected for adjusting the final product to the customer’s needs.

-

Ingelia ensures the engineering and industrial design of the own equipment, simulating and analysing its behaviour in the engineering software.

Castellano

Castellano English

English