Ingelia has developed a process of hydrotermal carbonization of biomass which enables the recovery of the carbon contained in the organic waste streams regardless of the humidity and heterogeneity to obtain a solid carbon based biomaterial (hydrochar). The hydrochar can be used as raw material for the industry substituting fossil fuels and as biofuel with a high GCV (gross calorific value), low humidity, high performance on combustion and without CO2 emissions. The solid biofuel can be obtained from a wide range of organic stuff. Industrial development made by Ingelia has been patented on the basis of their temperature and control system as well as their reactor. Ingelia could develop and implement the hydrotermal technology at industrial scale thanks to the scientific work performed by Nobel laureate Friedrich Bergius, and publications made by Prof. Markus Antonietti from Max Planck Institute, whose workshop about hydrothermal carbonization Ingelia joined in 2007. Ingelia has designed and built a Hydrothermal Carbonization Plant of Biomass that shows the viability of industrial implementation. Nowadays, Ingelia continues their R&D work on the process having the collaboration of the Chemical Technology Institute from Polytechnics University of Valencia.– CSIC. The HTC process dehydrates the carbohydrate under certain conditions of pressure, temperature and acidic environment, in relatively short times (4 to 16 hours).

Ingelia has developed a process of hydrotermal carbonization of biomass which enables the recovery of the carbon contained in the organic waste streams regardless of the humidity and heterogeneity to obtain a solid carbon based biomaterial (hydrochar). The hydrochar can be used as raw material for the industry substituting fossil fuels and as biofuel with a high GCV (gross calorific value), low humidity, high performance on combustion and without CO2 emissions. The solid biofuel can be obtained from a wide range of organic stuff. Industrial development made by Ingelia has been patented on the basis of their temperature and control system as well as their reactor. Ingelia could develop and implement the hydrotermal technology at industrial scale thanks to the scientific work performed by Nobel laureate Friedrich Bergius, and publications made by Prof. Markus Antonietti from Max Planck Institute, whose workshop about hydrothermal carbonization Ingelia joined in 2007. Ingelia has designed and built a Hydrothermal Carbonization Plant of Biomass that shows the viability of industrial implementation. Nowadays, Ingelia continues their R&D work on the process having the collaboration of the Chemical Technology Institute from Polytechnics University of Valencia.– CSIC. The HTC process dehydrates the carbohydrate under certain conditions of pressure, temperature and acidic environment, in relatively short times (4 to 16 hours).

The great advantage of HTC is that the process occurs in aqueous medium, so the moisture of biomass is not a problem. The process allows, on the one hand, concentrating the energy content from biomass into a solid biofuel, and the other, generating residual water that could be used as fertilizer on agricultural plantations.

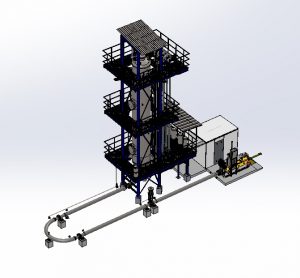

Construction and commercial validation of first Ingelia Industrial HTC plant

During July and August 2010, Ingelia carried out the start-up process of its own hydrothermal carbonization of biomass plant, which was designed and constructed also by Ingelia. This is the first industrial HTC plant worldwide capable of carbonizing biomass in continuous process by means of the HTC hydrothermal process. Since 2012, Ingelia operates this industrial prototype plant, demonstrating that its patented HTC process works in continuous, and that it is able to produce Biocoal (Hydrochar), and liquid fertilizer, from any type of wet organic waste, like the organic fraction of MSW, sewage sludge, agro-forestry residues and residues from food&drink industries (see NEWAPP FP7 European Project).

The successful results obtained during the demonstration campaigns carried out with all the above-mentioned materials, allowed Ingelia to start developing a business model to replicate the Industrial HTC concept in different countries.

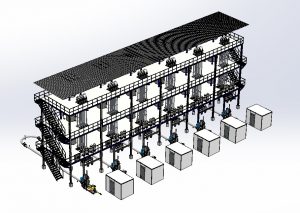

Scalability of new HTC plants

Biomass HTC plants are modular, so the processing capacity of biomass can be adapt to the Customer’s needings, from 7.000 Tn biomass/year. Furthermore, Ingelia can adapt, if required, its carbonization plant design to the current production process of the Customer. Plants build by Ingelia are fully automatized and can be monitored and operated remotely with the remote system.

1 reactor module

6 reactors module

The main product: Biocoal

The biocoal is homogeneous, whether biomass introduced on carbonization plant. It concentrates the energy power of biomass supplied with a LHV around 24 MJ/kg, similar to browncoal, with a carbon content between 54% and 62%.

-

Bio-coal combustion is uniform, so burning equipment are easier and cheaper

-

High density, so transportation and management costs are reduced

-

It occurs in porous form under water, so it is easy to apply a pressing-drying process

-

Elements such as K, Cl, etc.. are dissolved in the liquid phase, resulting in a coal with low salinity and ash melting points above 1250 ° C

-

Different post-treatments can be adapted for improving the quality of coal

-

Versatility, as bio-coal can be used for: electrical generation, co-combustion, pelletization, selling, direct combustion in order to obtain heat, or power.

Water balance

Castellano

Castellano English

English